CST Systems | Solutions for your corrugator and converting needs.

Our Products

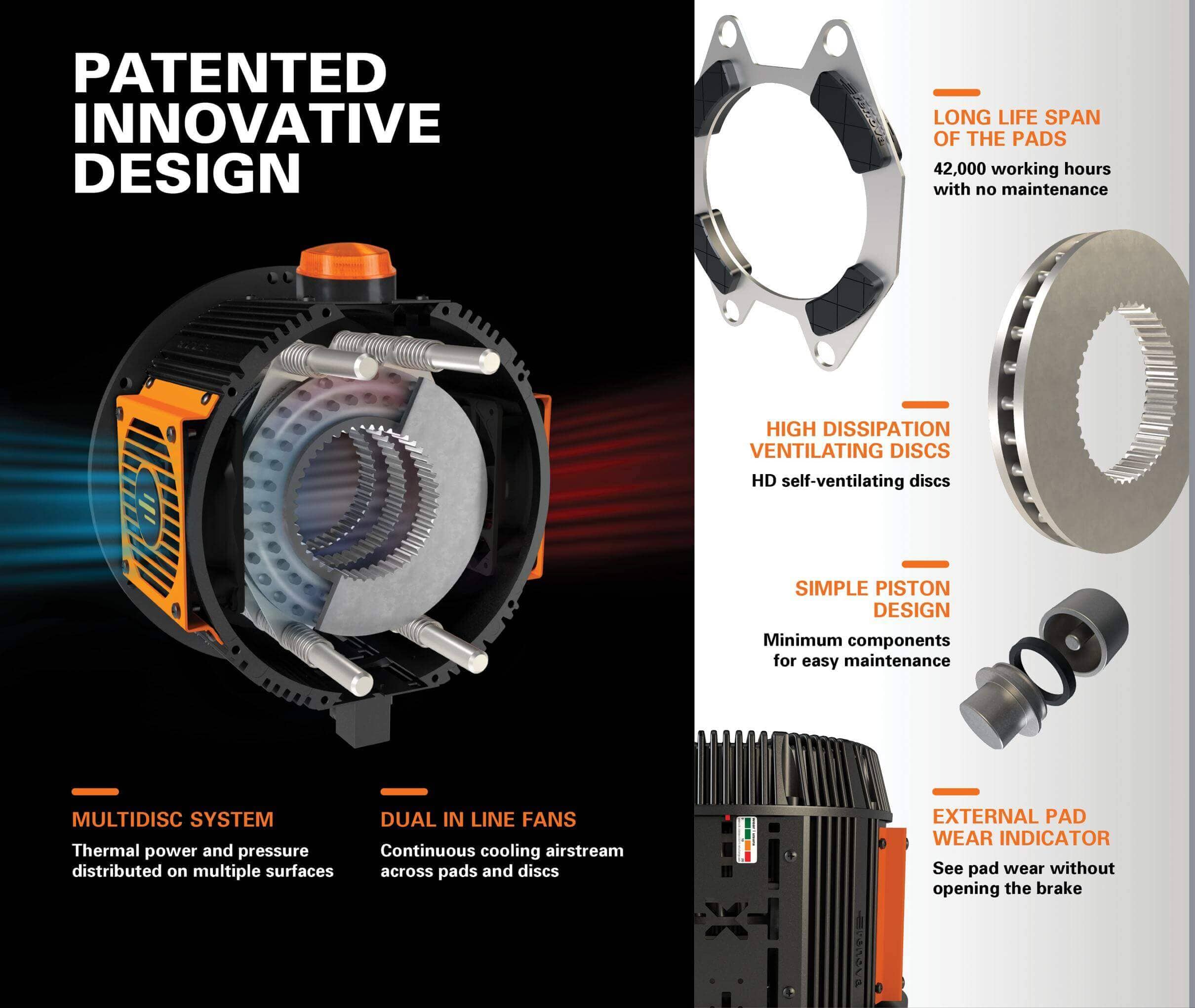

Turborex Heat Dissipation Brake (TxHD)

Turborex HD Brakes set the standard for consistent performance. How much downtime did the maintenance on your current brakes cost you this year? Do you know what would be possible if you eliminated all those costs and downtime for the next 5 years?

Maintenance teams love Turborex’s simple maintenance and 5-year brake pad life. Production teams love Turborex’s reliability, safety, and customizable features. We think you’ll find something about it that you’ll love too.

Testimonials

If I move to another plant, CST Systems is going to be my first call. I wouldn’t run a box plant without them.

The chucks are doing great. The expansion units grip well, and we have no more slippage on butt rolls.

The rolls are easy to remove from the chucks… we don’t have to use any tools to take them off.

We used to have a lot of problems with cores splitting, pusher plates coming off, core slippage and the nosecone just breaking off the end of the chuck. But since we put on the new one, we’ve seen significant improvement in core slippage and reliability… plus they’re just not breaking anymore.

They hold up very well and the whole corrugator team keeps telling me how happy they are about them. We haven’t had to change the pads at all since we got them, so it’s added a lot of extra time to our corrugator PMs.

I wouldn’t change a thing about your brakes. Most things, you say: “They’re great but I’d change this or that.” But CST Systems brakes are just about bulletproof. They’d stop a mac truck.

We were really surprised by the battery life! We’re used to having to charge after one shift, but it’s doing 3-4 shifts before we need to swap it out.

These are much safer than the pneumatic pushers we had to use before. I’ve tried all the other battery pushers this is the only one that can put up with the production floor long-term.