CST Systems | Solutions for your corrugator and converting needs

Testimonials

CST Sales and Service

Thanks for the great customer service. It’s nice to have a company to work with that follows through quickly with an issue.

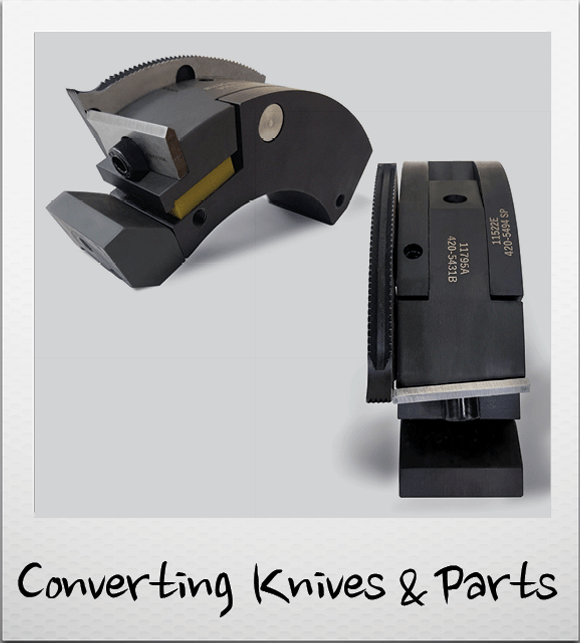

CST Clean-Cut Converting Knives

They are cheaper and better. Switching to y’all is a no brainer.

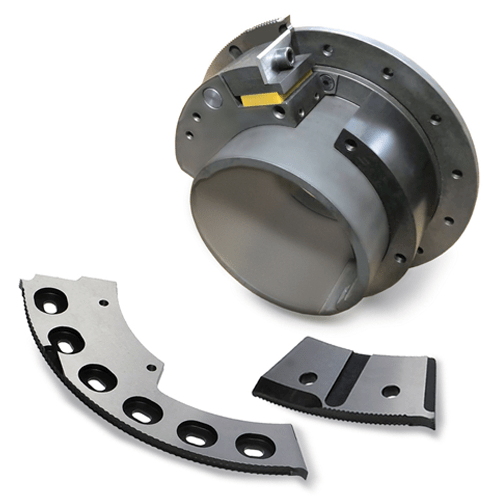

Waste Reducer Chuck

[If someone says a chuck is a chuck] they’ve never tried these [CST chucks]. I’ve been in this business for over 20 years and I can tell them that the right chuck makes a big difference in the maintenance and production of any corrugator.

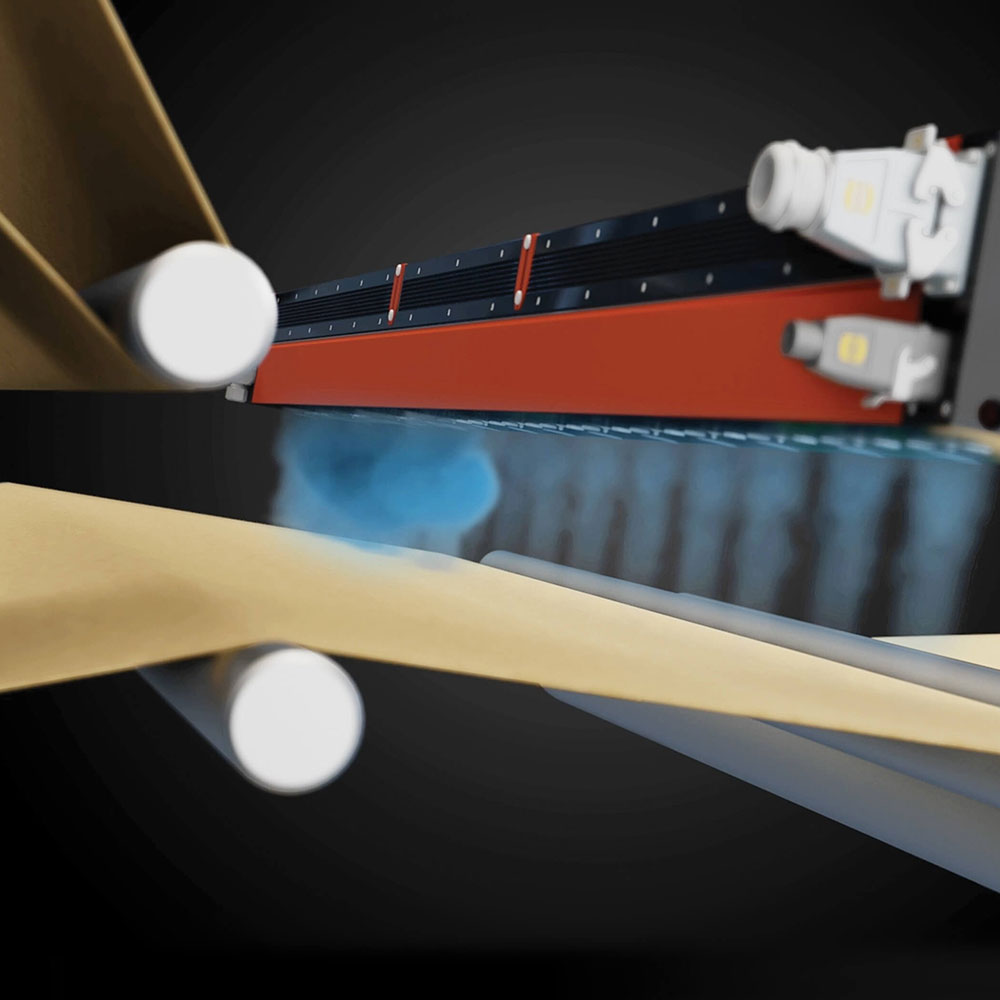

Renova’s Energy-Recovery Hybrid Brake – A groundbreaking innovation featuring a patented braking system that splices faster, provides higher safety, and includes an energy-recover motor.

See how much you can save with the Revolution Regenerative Brake System!