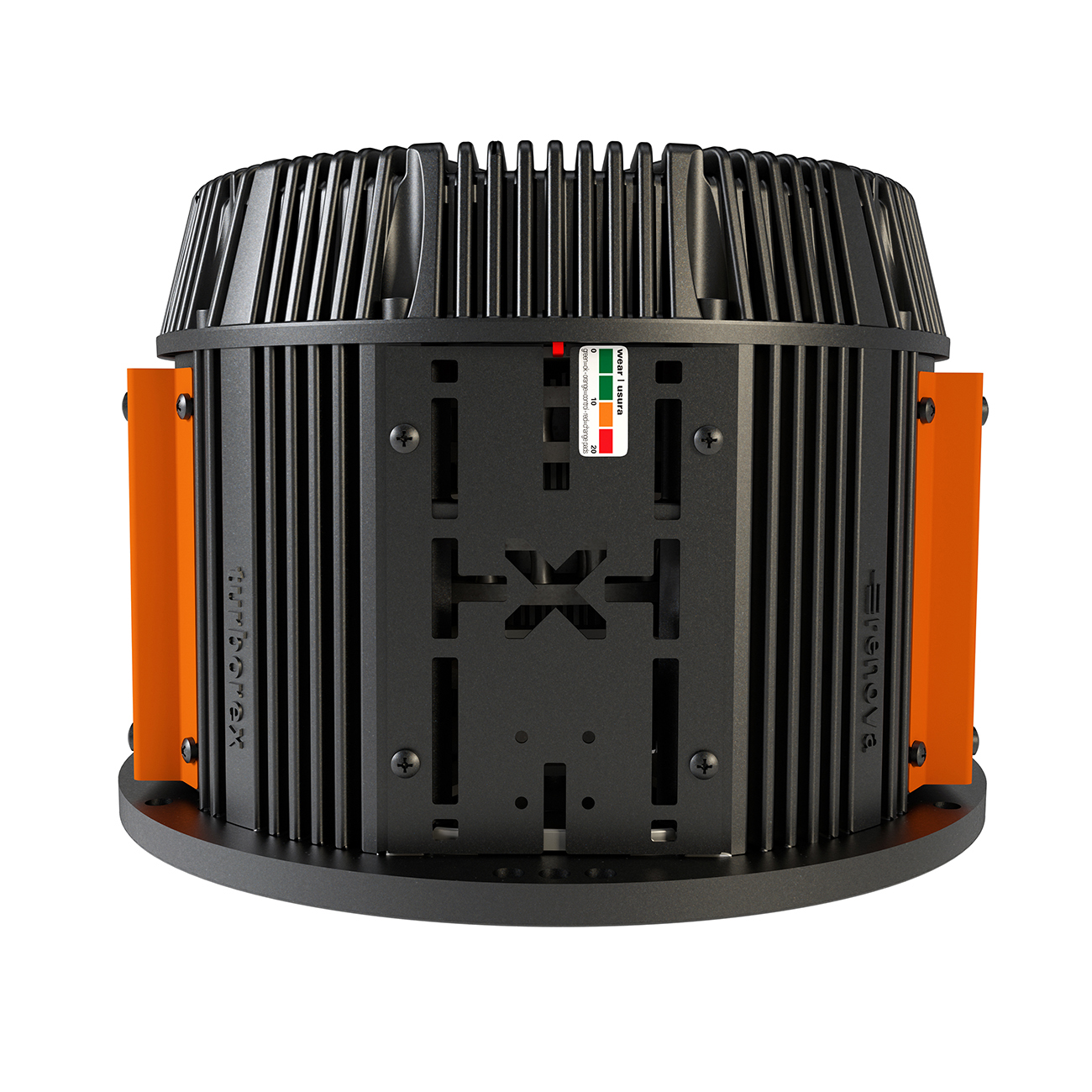

Turborex Brake System

Turborex Brake Upgrades All Existing Rollstands with Customized Adapters.

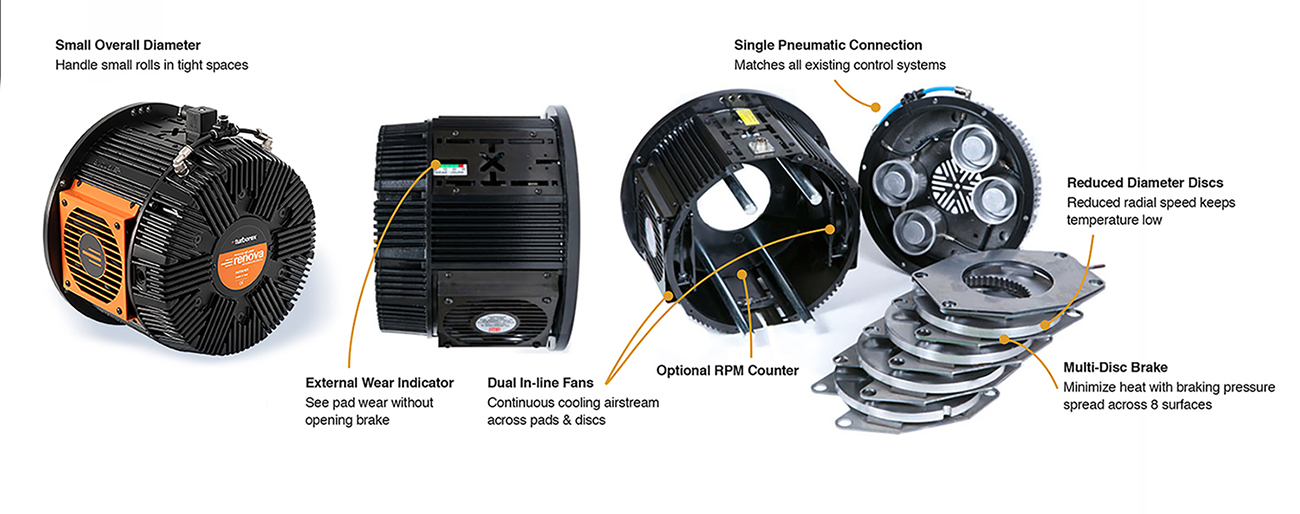

The Turborex Brake uses a new multi-disc system to distribute load over eight disc surfaces instead of the usual two, reducing the pressure on each pad by a factor of ten. With cooling air pushed through the brake by two high-speed fans, the Turborex Brake stays cool and inside the “no-wear zone” of the brake pads at all times — providing you with an extended lifespan on all internal parts. This means that we can guarantee at least five years with no replacement of brake pads and discs.

Because there is virtually no wear on the pads, there is no brake pad dust to contaminate your work environment. Because of our low operating temperatures, there is no brake pad glazing or squeaking. And because it carries an identical mounting system to various other brake systems, most customers will require no modifications on their machines to switch to the Turborex Brake.

- Description

- MORE INFO

- SPECIFICATION FORM

- MEDIA

Description

TURBOREX BRAKE UPGRADES ALL EXISTING ROLLSTANDS WITH CUSTOMIZED ADAPTERS

- Central hub custom-machined to existing shaft & key specifications

- High-temperature coating ensures continuous smooth action

- Mounting flange custom-machined to existing machine hole pattern

The Turborex Brake by Renova is the only forced air-cooled, multi-disc brake on the market. This patented system dramatically reduces internal temperatures and guarantees 42,000 maintenance-free working hours under extreme conditions, or approximately 5 years at 24/7 operation. A warning light activated via a temperature sensor alerts operations of increased operating temperatures due to possible fan malfunction and or contamination, or other interference.

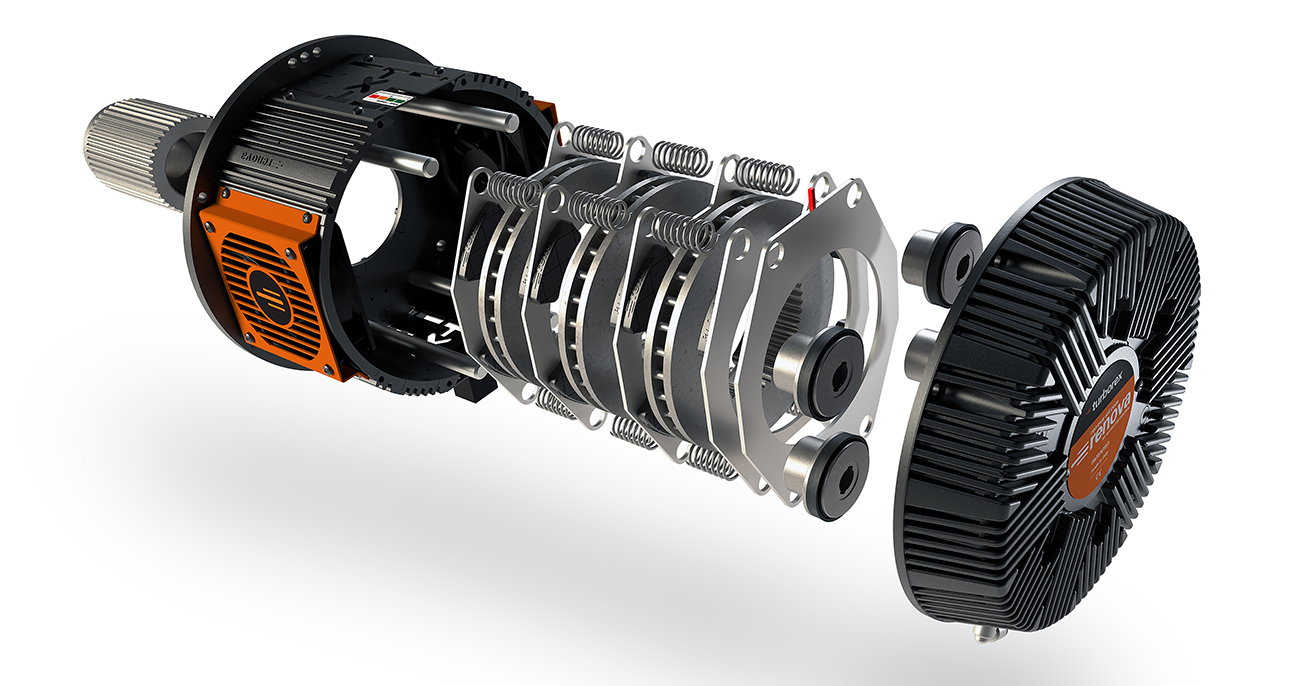

The system starts with the exclusive multi-disc system that spreads the braking pressure over 4 discs and 32 pads. The friction is widely distributed and this keeps any one component from overheating.

The heat generated by braking is handled by the dual in-line fan system. One fan blows air into the brake and the other blows air out. This consistently supplies cool outside air and pushes heated air out of the brake.

With the two high-speed fans, the reduced disc size, and the 8 braking surfaces, temperatures are kept low enough to keep the brake pads inside the “no-wear zone”—providing you with an extended life on all internal parts.

Because of the lowered temperatures, web tension control is improved at any line speed and brake pad wear and pollution are virtually eliminated. The Turborex Brake is 100% adaptable to all existing rollstands and Erhardt+Leimer bridge control system. No modifications are required on the machine to upgrade.

The Turborex Brake is the OEM brake for Fosber and Erhardt+Leimer.